We make the most hygienic range of liquid and paste fillers on the market.

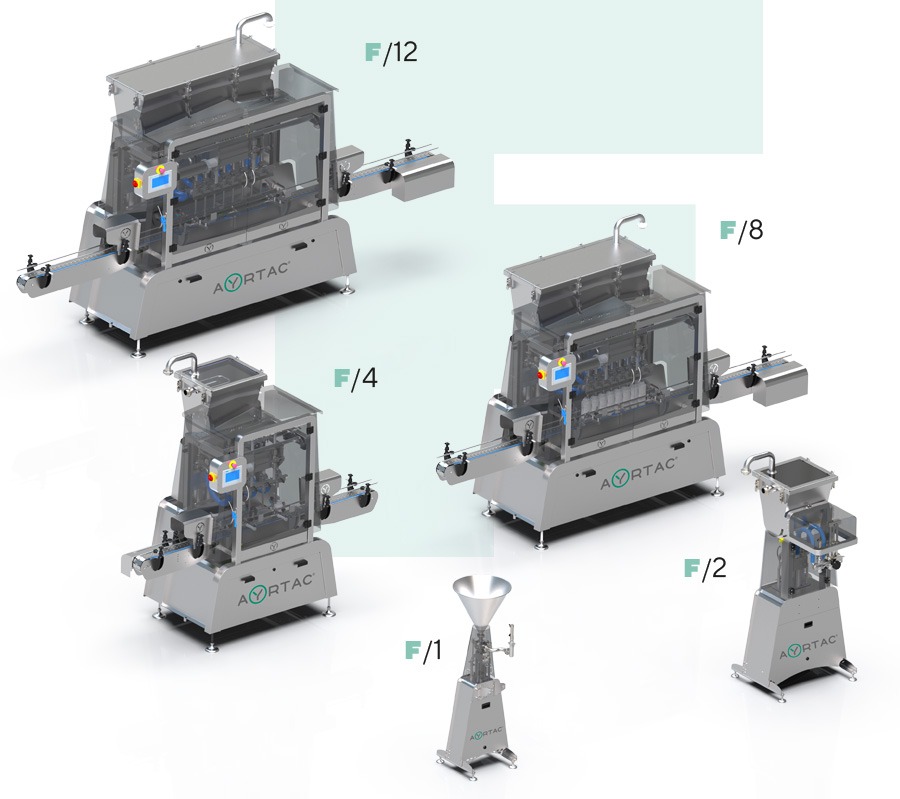

F Filler range

Select the model that suits your production needs.

F/1 | F/2 | F/4 | F/8 | F/12 | |

|---|---|---|---|---|---|

FILLING SPEED* | Up to 20 jars/min* | Up to 40 jars/min* | Up to 80 jars/min* | Up to 110 jars/min* | Up to 150 jars/min* |

TANK CAPACITY | 30 l | 50 l | 60 l | 120 l | 180 l |

DOSABLE VOLUMEN | 30-4.000 ml | 30-4.000 ml | 30-4.000 ml | 30-4.000 ml | 30-4.000 ml |

VOLUME PER PISTON | Up to 1.000 ml | Up to 1.000 ml | Up to 1.000 ml | Up to 1.000 ml | Up to 1.000 ml |

JAR Ø UP TO | – | 160 mm | 160 mm | 160 mm | 160 mm |

JAR HEIGHT UP TO | 260 mm | 260 mm | 260 mm | 260 mm | 260 mm |

ELECTRICAL REQUIREMENTS | – | 0,5 Kw | 1,3 Kw | 1,6 Kw | 2 Kw |

GENERAL DIMENSIONS | 600x600x1700mm 80 Kg | 1000x850x2100mm 400 Kg | 2700x1200x2200mm** 700 Kg | 3900x1200x2200mm** 1.000 Kg | 5200x1200x2200mm** 1.300 Kg |

PNEUMATIC CONNECTION | 6 bar | 6 bar | 6 bar | 6 bar | 6 bar |

FORMAT CHANGE | Manual | Manual | Manual (Optional automatic) | Manual (Optional automatic) | Manual (Optional automatic) |

SERVO/ELECTRONIC | No | No | Optional | Optional | Optional |

CIP PRE-INSTALLATION | No | No | Yes | Yes | Yes |

BOTTOM UP SYSTEM | No | No | Included | Included | Included |

TANK HEATING | Optional | Optional | Optional | Optional | Optional |

AGITATOR IN TANK | No | Optional | Optional | Optional | Optional |

* Estimated speed on an A314 container and with dosing of a tomato fried at 70º.

** Filler dimensions adjustable to customer requirements, depending on conveyor lengths

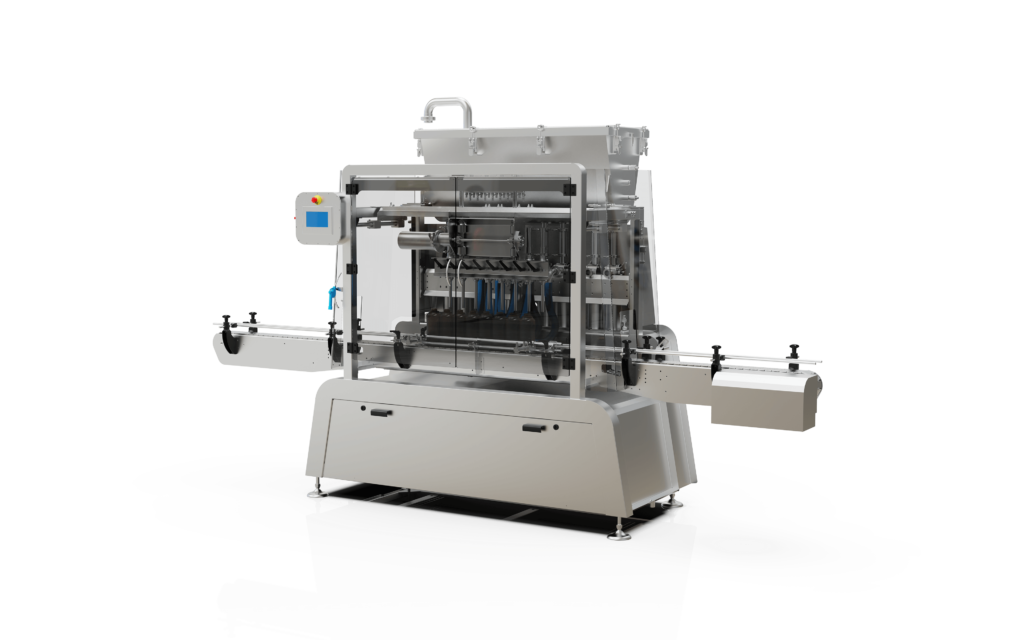

- HIGH PERFORMANCE -

Advantages of Ayrtac F fillers

They are not like the others.

They are the fastest and most complete fillers for liquids and paste products on the market.

Quick removal of the inner cylinders without tools

Automatic filling and format change control system

Hygienic design with two levels of cleaning zone

- SMALL PRODUCTIONS -

F/1 - F/2

Machines for small-scale production and growing packaging processes.

Very easy to use and versatile equipment.

F/1

With one head and only pneumatic system. Filling speed up to 20 containers per minute.

F/2

Two-head filler with pneumatic or electronic system. Filling speed up to 40 containers per minute.

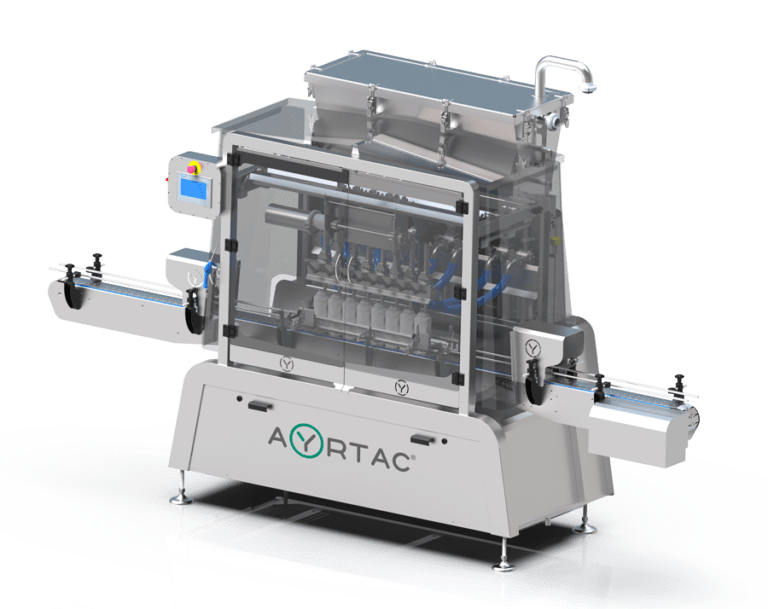

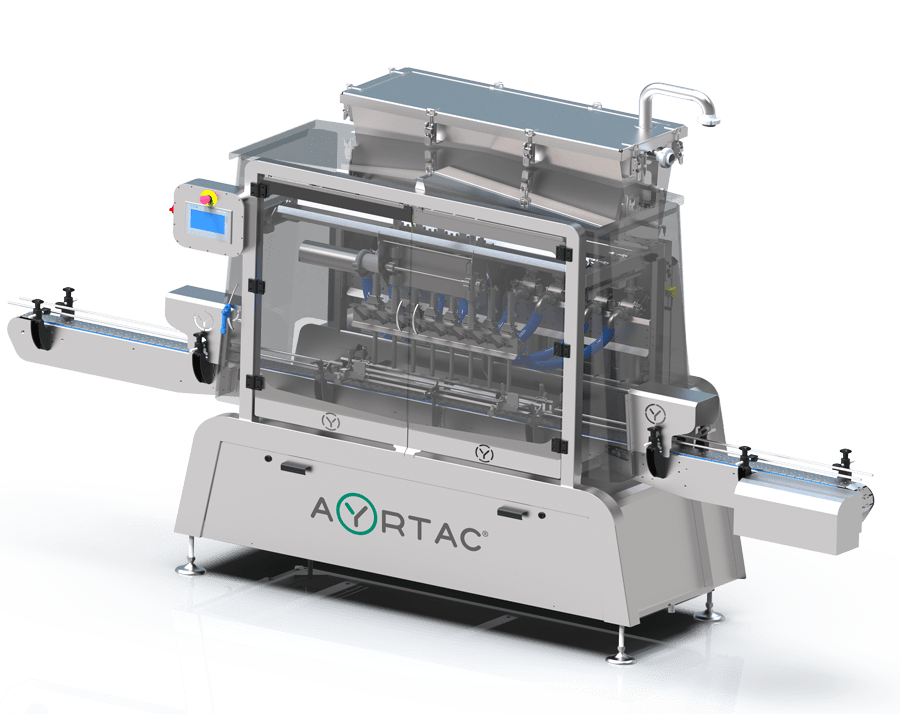

- MEDIUM AND HIGH PRODUCTION RATES -

F/4 - F/8

Equipment designed to cover medium and high production rates, with quick format changeover and cleaning.

F/4

With a hopper capacity of 60 litres and 4 heads, it reaches a filling speed of up to 80 containers per minute.

F/8

Designed for medium and high production rates, with a filling speed of up to 110 containers per minute.

- TOP OF THE RANGE -

F/12

High-performance filler ready to tackle high production rates.

It has 12 heads, a 180-litre tank and filling speed up to 150 containers per minute.

- MAINTENANCE -

Cleaning system

A unique cleaning system with tool-free dismantling makes our fillers extremely effective and efficient.

Standards around cleanliness are higher every day, which is why we have designed a two-level structure for easier dismantling, maintenance and cleaning of the ducts.

We specialise in providing sustainable and customised solutions for production and packaging processes.

We have the equipment you need to scale your business.